Commercial roofs, with their various forms and constructions, play a critical role in safeguarding buildings from the elements. However, over time, moisture can silently undermine their integrity. To mitigate this risk, we rely on specific tools to detect moisture. In this article, we explore the most used tools for managing low-slope roofs.

Many tools are available for detecting and measuring moisture on commercial roofs. Each possesses unique capabilities and strengths, each suitable for different needs and scenarios. These tools fall into two broad categories: non-destructive and destructive—each playing a vital role in ensuring the health of commercial low-slope roofs.

Let’s look at the advantages and drawbacks of both.

Non-Destructive Roof Testing

Captured by Structura View.

Non-destructive testing methods, such as thermal imaging, electrical capacitance scanners, and nuclear density gauges are examples of non-invasive tools. They do not require any physical damage to the roof’s surface.

Benefits of non-destructive methods include:

- Efficiency: Non-destructive testing is typically quick and efficient, able to cover large areas, and provide immediate results making it suitable for routine inspections.

- Non-Invasive: The individual test methods do not require puncturing the roof to produce results, but destructive testing is always recommended to validate initial observations.

- Surface-Only Assessment: Non-destructive methods primarily assess changes in temperature, electrical conductivity, or neutron moderation in the roof, indicating potential wet and dry areas. In thermal imaging, wet areas can show up either as hot or cold depending on various factors.

Destructive Roof Testing

Destructive testing methods, such as core sampling and probe testing, offer highly precise results. They allow you to obtain accurate data about roof composition, moisture content at each layer of the roof’s structure, and the condition of the roof in the tested area.

Captured by Structura View.

Benefits of destructive methods include:

Comprehensive Data: Destructive testing provides deep insights into the layers of the roof structure. It not only reveals the presence of moisture but also helps assess material integrity, detect structural issues, and identify potential weaknesses.

Analysis: Some destructive tests require the collection of core samples for on-site or laboratory testing, enabling a thorough examination that can reveal concealed issues not detectable through non-destructive techniques.

Damage: The primary drawback of destructive testing is that it damages the roof surface. The process involves cutting or puncturing the waterproofing membrane.

Repairs: After destructive testing, patching is required.

Destructive testing methods typically follow non-intrusive assessments and are used to validate the assumptions gained from non-intrusive testing and collect precise moisture data. Keep in mind that destructive testing will need to be followed by some type of roof patch.

By understanding the benefits and considerations of each approach, you can make the best choice to ensure the longevity and health of your commercial roof.

Non-Destructive Tools

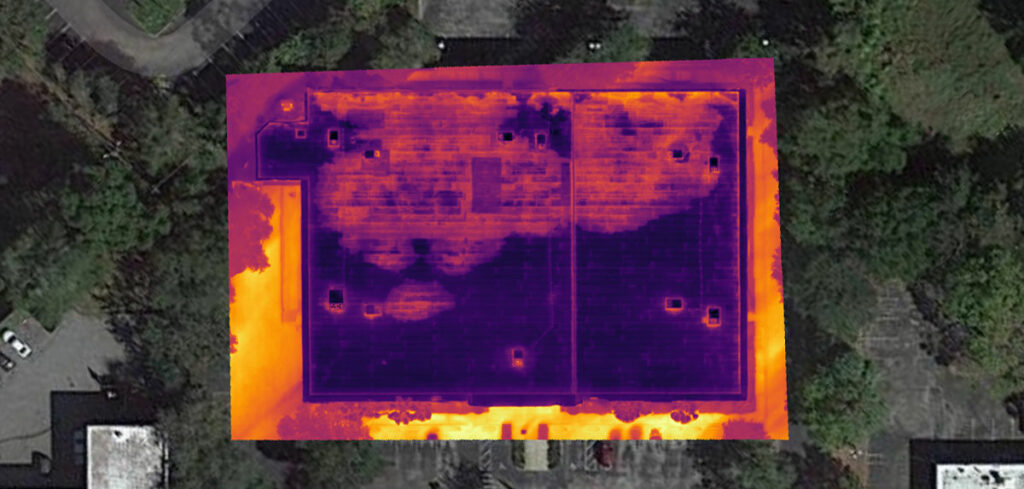

1. Thermal Imaging

In the realm of non-destructive methods for identifying moisture in roofs, thermal imaging takes the spotlight. Thermal imaging relies on the use of infrared cameras to show variations in surface temperature, which, in turn, can signal the presence of moisture hidden beneath the roof’s surface. What makes thermal imaging noteworthy is its speed, non-invasiveness, and high effectiveness.

Captured by Structura View.

Thermal imaging, often referred to as thermography or infrared imagery, is a straightforward and powerful technology used in the inspection of various structures, including commercial roofs. It operates on a fundamental principle: the detection of temperature differences.

In the context of roofing, thermal imaging entails the following steps:

- Equipment Setup: A handheld or small Unmanned Aerial Vehicle (sUAV)-mounted thermal imaging camera is used. This camera creates images in which different temperatures are represented by varying colors, producing what’s known as a thermogram.

- Scanning the Roof: A qualified technician scans the surface of the roof. The camera records temperature differences across the roof’s surface.

- Data Interpretation: The thermogram created by the camera is then analyzed. Thermal images captured by a drone using a pre-programmed route can be stitched together into one large map for analysis—handheld thermograms cannot be stitched together. Depending on the roof, warm or cool areas on the image may indicate potential moisture intrusion based on many factors. The areas with temperature anomalies are identified for evaluation.

Advantages of Thermal Imaging:

- Speedy Assessment: One of the significant advantages of thermal imaging is its speed. A technician can quickly scan the entire roof and identify potential moisture issues without intrusive methods or extensive labor.

- Non-Invasive: Thermal imaging is a non-destructive technique. It doesn’t require cutting into the roof or creating holes.

- Large Area Coverage: Thermal imaging can cover a large area in a single scan, making it highly efficient for both routine inspections and identifying specific areas of concern.

While thermal imaging is a powerful tool for moisture detection, it’s essential to note that it provides an initial assessment. It’s effective at identifying potential trouble spots. However, further testing, such as core sampling, may be necessary for confirmation and to determine the extent of moisture intrusion.

2. Electrical Capacitance/Impedance Testing

Captured by Structura View.

Impedance scanners, like the Tramex Dec Scanner, sit on the roof and roll over the roof membrane. A quality electrical capacitance scanner offers multiple ranges of sensitivity and can penetrate the roof to 6″ or more. These scanners function well on many roof membranes and insulation thicknesses. They provide instant readings, which can be used to plot moisture maps, identify areas for taking core samples, and locating anomalies found in thermal scans. Electrical capacitance scanners may not be suitable for roofing with electrically conductive or metal-faced membranes—review the technical data of the specific equipment manufacturer for details.

It’s important to note that the data provided by these scanners displays the relative measurement of moisture, not an absolute wet or dry reading. Accurately interpreting these readings requires experience and a validation process like taking a core sample to correctly understand the data.

3. Electronic Leak Detection

Electronic Leak Detection (ELD) refers to products and services that use electrical conductance to locate breaches in roofing and waterproofing membranes.

The four ELD methods are described in detail in ASTM D7877 and include scanning platform, vertical roller, vector mapping, and high voltage. These testing methods are typically used in new construction as a QC tool for locating breaches in the membrane. Specifically the electrical path between the membrane and conductive substrate or medium such as concrete or TruGround. They can also be used to locate active leaks but require water intrusion from the membrane down to an electrically conductive deck.

The D7877 Includes the Following Terminology:

Leak: Any unintended opening, perforation, slit, tear, puncture, crack, hole, cut, or similar breaches through an installed waterproofing membrane that may allow the passage of liquid. Scratches, gouges, or other aberrations that do not completely penetrate the membrane are not considered to be leaks as the term is used in this guide although they may be defects requiring attention.

Breach: As defined for this guide, a membrane breach is a defect in the membrane that allows surface water to reach the substrate below.

The four ELD methods use various testing tools, each suited to specific conditions. Some function on wet roofs, while others are designed for dry roofs. Most testing methods exclusively only work on non-conductive membranes, while the Low Voltage IntegriScan by Detec Systems is capable of testing both moderately conductive and non-conductive membranes (ASTM D8231).

In wet roof testing, the targeted area needs to be saturated with moisture and standing water should be avoided. On the other hand, when conducting dry testing, the roof must be entirely free of moisture.

Non-conductive membranes comprise materials like thermoplastic polyolefin, polyethylene, polypropylene, polyvinyl chloride, and bituminous material. In contrast, moderately conductive membranes include materials such as black EPDM, cold fluid coatings containing carbon black or metal, and coatings with a high moisture content.

All ELD methods are listed in ASTM D7877. ELD includes low voltage and high voltage, which have the same physics and basic requirements: ELD requires an exposed membrane, a ground connection, a conductive substrate, and an electrical path from the membrane to the conductive substrate. The differences between the four ELD methods are the testing apparatus, the testing procedure, and limitations.

Let’s explore the four ELD methods.

Testing method: Vector Mapping

Membrane type: Non-Conductive

Electric Field Vector Mapping can be a valid tool for leak detection and quality assurance. Water’s conductivity enables electrical current to flow, aiding in the precise localization of leaks.

Courtesy of Buckleys International.

For wet testing, breaches enable water infiltration into the roof’s system and must travel to an electrically conductive substrate below the membrane. Water is an electrical conductor, therefore when water touches a grounded object, an electrical circuit is completed.

Vector mapping requires the testing area, and all grounded objects, such as drains, to be isolated using a perimeter or conductor cable. Water must then be applied to the surface of the membrane to carry the electricity from the electrified cable, to the breaches in the membrane. The detector unit connects two hand-held probes, which are placed in contact with the surface of the membrane. By assessing the voltage difference between the test probes, the detector unit guides the operator to pinpoint the exact breach location. If the membrane can be dried, breaches found can then be repaired and if fully cured, retested promptly to ensure a proper repair was completed.

Due to the requirement of isolating the testing area, vector mapping is not suitable for testing transitions, details, or vertical surfaces.

Testing method: Scanning Platform & Vertical Roller Testing

Membrane type: Non-Conductive & Moderately Conductive

The IntegriScan scanning platform and vertical roller units are also a wet testing method and come together as a package. Water is used during the test which carries the electrical current from the testing unit, through the breach in the membrane, to the conductive substrate below.

Courtesy of Detec Systems.

The IntegriScan method was developed to simplify ELD, making testing more versatile and user friendly. The low voltage scanning platform is utilized on horizontal surfaces that are non-conductive and moderately conductive, including membranes such as black EPDM and cold fluid coatings containing carbon black.

The platform unit has a built in isolation area, limiting the testing area to 24”x10” at all times. While the technician pushes the platform along the surface, the equipment’s electronics will alert the technician visually and audibly when the unit is directly over a breach. The low voltage vertical roller is a separate attachment which is used for testing verticals, transitions, details and small horizontal surfaces. The roller apparatus currently tests non-conductive membranes only, but Detec Systems will soon release a vertical unit for conductive membranes.

ELD testing in new construction requires a conductive substrate directly below the membrane. Typically, ELD is performed on waterproofing membranes installed directly to structural concrete. In conventional roofing, a conductive medium must be added directly below the membrane to enable valid ELD for quality control testing. Detec Systems developed the conductive primer which can be applied to the non-conductive surface directly below the membrane (typically coverboard). Membranes can be adhered, torched, fastened, fluid applied or loosely laid. Additionally, the conductive primer enables both low voltage and high voltage ELD in new construction, and for the life of the roof.

Courtesy of Detec Systems.

The IntegriScan scanning platform and vertical roller are the only ELD methods that are listed in both the ASTM Guide D7877 and ASTM Practice D8231 and are FM approved ELD methods.

Testing method: High Voltage

Membrane type: Non-Conductive

Dry testing is a faster process compared to wet testing. It’s ideal for roofing membranes and roof compositions typically classified as non-conductive, yet exhibit minimal electrical conductivity. While versatile, you will need to verify this method works with your specific roof composition.

Courtesy of Buckleys International.

High voltage, spark, or holiday ELD is a faster process compared to wet testing. This method utilizes up to 40,000 volts and requires the surface of the membrane to be completely dry. High voltage ELD requires a direct vertical air gap for the equipment to locate a breach. It is also capable of sparking through thin spots in some coatings.

High voltage equipment is utilized on horizontals, verticals, and transitions but is only capable of testing non-conductive membranes. The technician moves the testing apparatus across the membrane. At the location of a breach in the membrane, the equipment will spark and electronics will beep.

The primary limitation of high voltage is that it cannot be performed in wet conditions. This unit cannot test in inclement weather or if there is any dew or frost on the membrane. Any moisture present on the membrane will cause the equipment to go into alarm. This equipment must also be calibrated for the membrane’s millimeter thickness. If the voltage is set too high, it can potentially burn through the membrane. Additionally, this unit should not be used in combustible areas.

Advantages of Electronic Leak Detection:

Breaches in the membrane can be pinpointed and often repaired and retested the same day. If the contractor is onsite and the membrane is dry, then repairs can be made. Retesting can only be done if the repair is fully cured.

Defects can be mapped on a visual image or a CAD plan. Defects, voids, breaches, and holes in the membrane is what ELD is locating. If a plan of the area is provided, any ELD testing agency can create a scan or breach map.

Capable of detecting all breaches, even pinhole and capillary action leaks. All ELD methods are capable of detecting breaches. It all comes down to testing within their limitations and the technician performing the work.

Suitable for both horizontal and vertical surfaces. 3 of the 4 ELD methods can work on horizontals and verticals. Typically, you’ll never see vector mapping used on verticals due to having to isolate the wall and the need for a continuous water path from the wire to the breach.

Less expensive, faster, safer, and more reliable than flood testing.

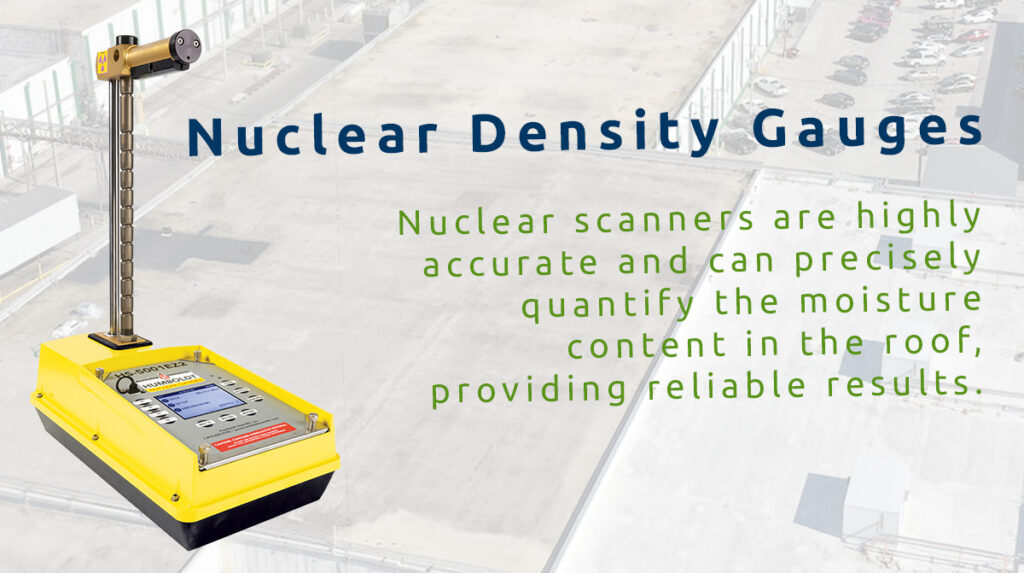

4. Nuclear Density Gauge Scanners

Nuclear scanners stand as a powerful tool, offering a unique approach to identify moisture-related issues. These devices, often referred to as nuclear roof moisture meters, employ nuclear technology to provide highly accurate measurements.

Courtesy of Humbold Mfg. Co.

Nuclear density gauges devices utilize a small, safe, and controlled radioactive source, which emits low-energy neutrons. When the emitted neutrons encounter hydrogen atoms in the roof’s structure, present in water molecules, a process known as neutron moderation occurs. This process slows down the neutrons and changes their direction.

The nuclear scanner’s sensor detects these moderated neutrons and quantifies their energy level. The recorded data is then processed to create a visual representation of the roof’s moisture points on a map of the roof. By analyzing the moisture map, areas with abnormal moisture levels are identified. These areas may signify potential moisture intrusion points.

Advantages of Nuclear Scanners:

- High Accuracy: Nuclear scanners are highly accurate and can precisely quantify the moisture content in the roof, providing reliable results.

- Non-Invasive: These devices are non-invasive and do not require physical contact with the roof’s surface. Nuclear scanners work on heavily ballasted roofs.

- Rapid Results: Nuclear scanning offers immediate results.

It’s crucial to note that nuclear scanning, despite its high accuracy, involves the use of a controlled radioactive source. The drawback of nuclear testing lies in the burdensome regulatory requirements associated with its use. Operating these devices requires licenses, strict adherence to regulations for storage, transportation, and use, as well as mandatory security inspections. Furthermore, the technology can only be operated by trained professionals to ensure both safety and accurate results.

Destructive Tools & Methods

In the realm of roof moisture detection, destructive methods have long been trusted for their ability to uncover hidden issues that may compromise the integrity of roofing systems. These techniques involve physical interventions and assessments, often considered ‘destructive’ due to its intrusive nature.

In this section, we’ll explore two key methods that provide a deeper understanding of moisture levels and material integrity.

Captured by Structura View.

1. Electrical Resistance Testing – Moisture Probes

One of the earliest and most effective ways to assess moisture is the use of handheld moisture meters equipped with specialized probes that are inserted into the roofing material. The probes are designed to accurately measure the moisture content of each layer of the roof’s composition. The depth of the probe is adjusted to suit the specific requirements of the assessment. Moisture probe testing is praised for its precision and the invaluable insights it yield.

Advantages of Handheld Moisture Meters with Probes:

- Precision: These devices are highly accurate in measuring moisture content and provide real-time readings that inform decision-making.

- In-Depth Insights: By directly testing the roofing material, the results give insights into the moisture content at different layers, allowing for a comprehensive assessment.

- Immediate Feedback: The real-time data provided by handheld moisture meters allows for on-site decision-making, making them particularly useful for repairs and maintenance.

2. Core Sampling

When it comes to a thorough evaluation of a roof’s condition and moisture levels, core sampling takes center stage. This method involves the extraction of small sections or ‘cores’ from the roof for subsequent moisture analysis. Many types of analysis can be done on-site and more specialized analysis can be done off-site in a laboratory. The insights gained from core sampling are invaluable, providing a comprehensive understanding of moisture levels, material integrity, and validating thermal data and other assumptions.

The Core Sampling Process

- Strategic Selection: Based on preliminary non-destructive data from thermal imagery, electric leak detection, or nuclear scans, core sample locations are selected. The samples are used to validate assumptions.

- Extraction of Roof Cores: Trained professionals carefully extract small sections of the roofing material, known as ‘cores.’

- Analysis: The extracted cores are subjected to meticulous analysis on-site, and core samples can also be sent to a laboratory.

Advantages of Core Sampling

- Comprehensive Insights: Core sampling provides a detailed analysis of the roof, including: relative and absolute moisture levels for each layer of the roof, roof depth, deck temperature, and material integrity.

- Validation: It serves as a validation method, confirming the accuracy of non-destructive testing results and providing a reliable benchmark for decision-making.

- Data-Driven Decisions: The data obtained from core sampling ensures that actions taken for repairs, replacements, and maintenance decisions are based on accurate insights.

While destructive methods may involve some intrusion, their precision and ability to provide in-depth insights make them essential components of a comprehensive moisture detection strategy. By integrating these methods into moisture assessment processes, professionals can ensure a thorough evaluation of a roof’s condition, enabling informed decision-making and effective maintenance practices.

Key Insights

To protect your commercial low-slope roof, you can choose between non-destructive and destructive tools and methods. Non-Destructive test methods do not require puncturing the roof to produce results, but destructive testing is always recommended to validate initial observations. Destructive Roof Testing provides precise data, plays a critical role in conducting a comprehensive evaluation, and empowers you to make well-informed, data-driven maintenance decisions.

Strategically integrating the right combination of non-destructive and destructive assessments is essential for the health and longevity of your commercial roof. Master the art of testing your commercial low-slope roof with the right tools and techniques to accurately observe and understand roof conditions.