Commercial Roof Manufacturers

Successful commercial roof installation and warranty compliance checks

As a high quality roof manufacturer, your roofing materials are constantly being put to the test. Commercial roofs are subject to heavy loads, moisture accumulation, improper maintenance, and other unavoidable issues.

When your roof is not installed or maintained properly, it will not perform to your standards. Your clients may not be satisfied with your roof, even though you’ve done your part. What if there was a fast and efficient way to ensure your roof material is being used correctly?

Protected reputation

Warranty compliance

Insurance claim assistance

Investigated failures

Longer-lasting roof material and happier clients

Structura View provides roof manufacturers with the quality assurance tools they need to keep clients happy. During installation, Structura View can monitor the project and catch any issues early. Routine inspections of client properties help them stay compliant with any warranties.

And if disaster strikes, Structura View can help both the roof manufacturer and the client understand exactly what failed and why.

Building enclosure consulting services for commercial

roof manufacturers

Routine Commercial Roof Inspections

Routine Commercial Roof Inspections

Visual Drone Inspections

Visual Drone Inspections

Drone Thermal Imaging and Scanning

Drone Thermal Imaging and Scanning

Moisture Mapping for Roofing Systems

Moisture Mapping for Roofing Systems

Detailed Roof Condition & Enclosure Reports

Detailed Roof Condition & Enclosure Reports

Construction Quality Assurance Observations

Construction Quality Assurance Observations

Roof Moisture Scan Helps Manufacturer Mitigate Unnecessary Liability

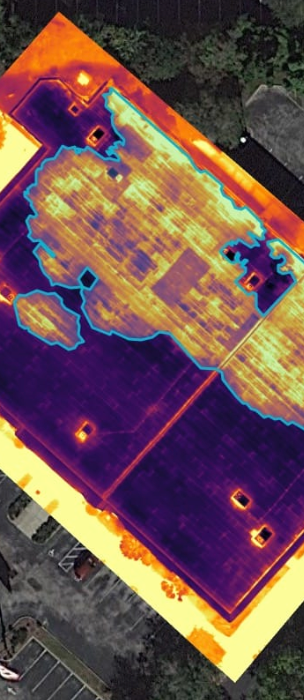

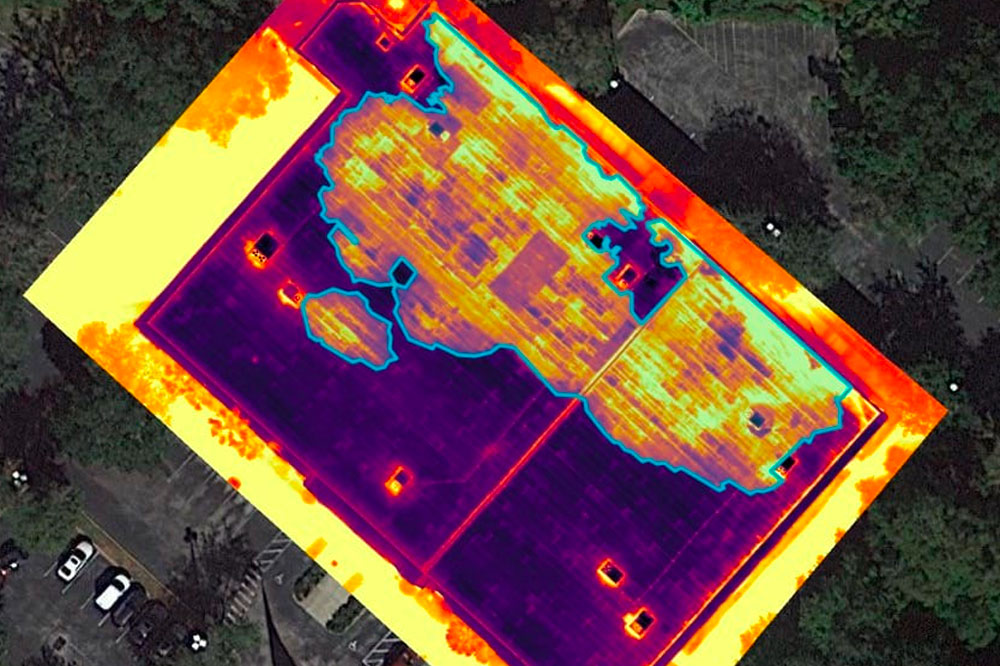

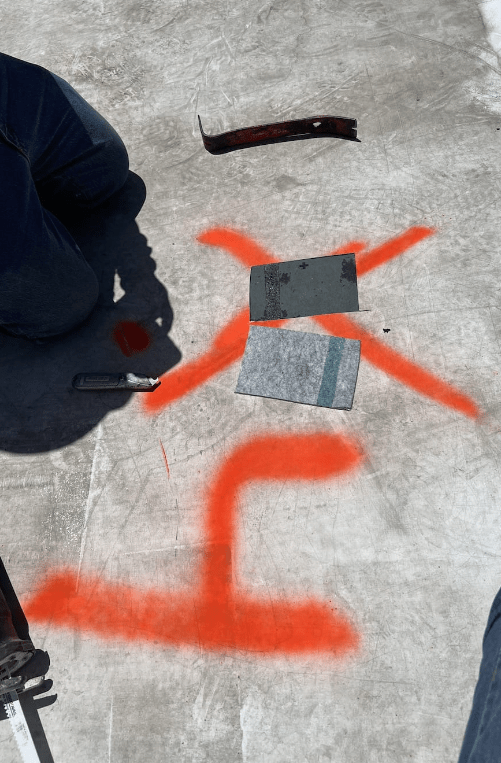

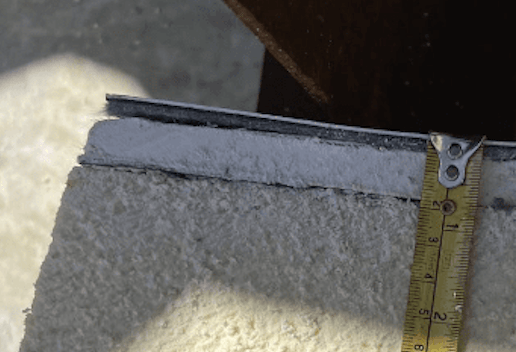

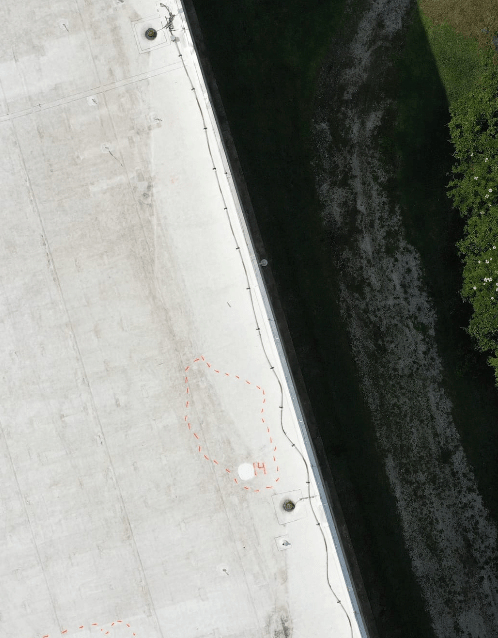

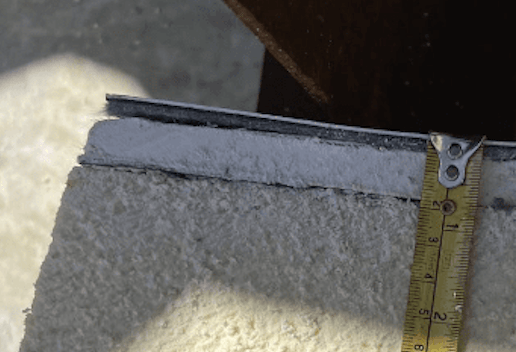

Structura View partnered with a roof coating manufacturer to perform a moisture mapping assessment on an older low sloped roof system. The property owner and roofing contractor wanted to look at getting the roof coated and warranted. For them to get this, they needed to perform a moisture scan to ensure moisture is not going to be getting trapped in the roof system.

This roof system consisted of a modified bitumen membrane, ISO insulation and a metal deck. Our team observed 14,131 square feet of moisture in the roof and the roofs total size was 32,568 square feet. Due to 43.4% of the roof being wet, this roof was not a financially viable option to install a roof coating. The scan helped give the manufacturer confidence in knowing they were not warranting an installation that would have exposed them to substantial unnecessary liability.