Oftentimes, we are asked to conduct inspections of commercial roofs to detect internal moisture damage when an insurance claim needs to be processed. Whether we are representing an insurance carrier or a policyholder, we always work hard to provide the highest-quality results possible through our infrared roof and wall inspections. Two of the most important factors in determining the quality of the results are the weather conditions and the timing of the inspection.

We often work with a Dallas-based engineering firm that represents many insurance providers on claims across the United States. We enjoy working with engineering firms like this one because they care about providing detailed and complete roof inspections so that they can clearly determine whether or not the roof damage was actually caused by the claimed weather event. In spite of the fact that they do represent the carrier, they strive to provide an unbiased his firm always carries out very thorough inspections.

For this claim in Wichita Falls, Texas, we conducted a thermal roof inspection, as well as a Tramex moisture meter inspection. Prior to us arriving on the job site, the engineering firm visually inspected the roof. They also took core samples at various places on the roof to get an understanding of the roof’s construction.

The property’s two largest roofs each had varying insulation, which led to very different results in the thermal imaging we conducted. While both of the roofs had a metal deck and a standard weld layered mod bit roof membrane, the smaller one had 3 inches of ISO boards as insulation. The larger roof also had 3 inches of ISO boards, as well as a tar membrane and SPF foam with a modified bitumen membrane.

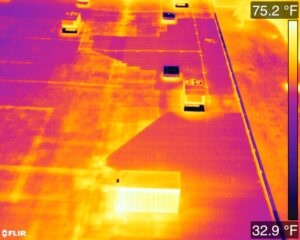

Because the site was located within military airspace, we were not authorized to fly above 100 ft. AGL (above ground level). This height is not ideal to complete roof inspections but still had no trouble determining which areas of the roof had suspected moisture present. However, because we had to fly so low, we couldn’t provide calculations on how much suspected moisture was found in the structure.

The foam insulation responds differently to ISO boards when moisture is present. Over time, once a leak point is created, the whole ISO board will absorb water. When a thermal scan is conducted of this kind of roof that has experienced leaks, sometimes a grid pattern is observed.

The picture to the left reflects what the IR looked like when studying saturated ISO boards.

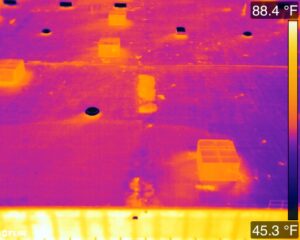

Conversely, the foam insulation material does not absorb water nearly as much. When a thermal scan of a roof with foam insulation is produced, the patterns are much smaller and usually confined to the areas where the leak point was created, as pictured left.

After completing each thermal scan, the results reflected the above explanations.

One of the largest difficulties when conducting thermal scans on roofs with multiple layers is determining the moisture levels present in the bottom layer since the upper layers insulate the moisture reading from getting all the way to the roof’s surface.

Even though there were many challenges associated with this roof inspection, we were able to accurately determine the areas of suspected moisture, which helped the engineering firm and insurance company process the claim.