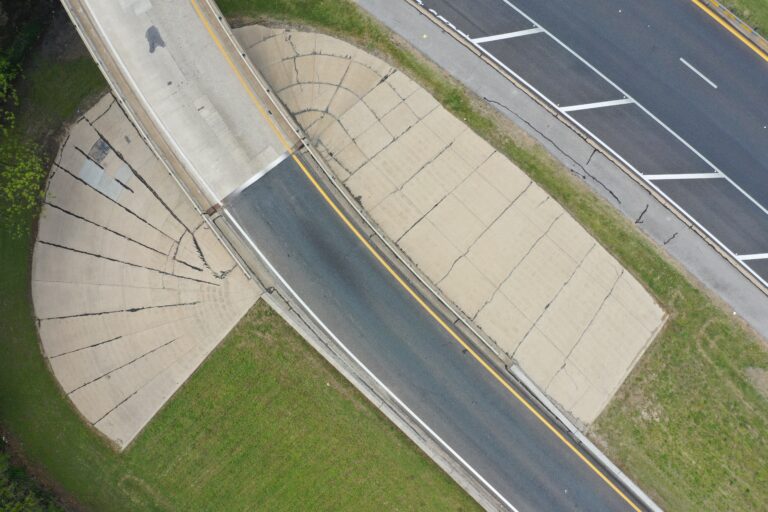

Hundreds of thousands of people travel on the Dallas North Tollway on a daily basis, and they pay for it. The drivers hope to experience a faster commute time and better traffic and expect the roadway to be properly maintained and fully operational. Bridge structures throughout the country are required to be inspected every 2 years for issues observed visually. We are often involved in performing inspections on bridge structures to study portions of the structure that are not easily inspectable through traditional inspection practices.

This project was unique compared to past bridge inspections we have been involved in. This time our purpose was to identify delaminations in the bridge deck by deploying drone-based thermal imaging. The traditional form of inspecting for delaminations in road and bridge decks is called a Chain Drag Survey. This process involves needing to close the road to drag chains over the road documenting the returning sound waves that indicate voids in the deck and help map them out.

Process Comparison

Chain dragging is a highly effective process for identifying delaminations. First up is to schedule road closures according to anticipated efficiency. Once in the field, the process involves dragging chains one lane at a time across the bridge recording acoustic readings along the way. This process requires manned road closure teams, a driver for the truck, and staff for recording and observing the process. This process can be efficient and highly effective.

The Project

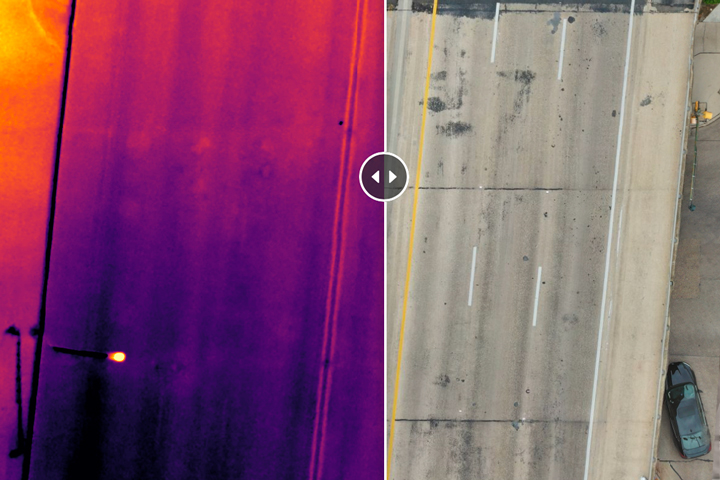

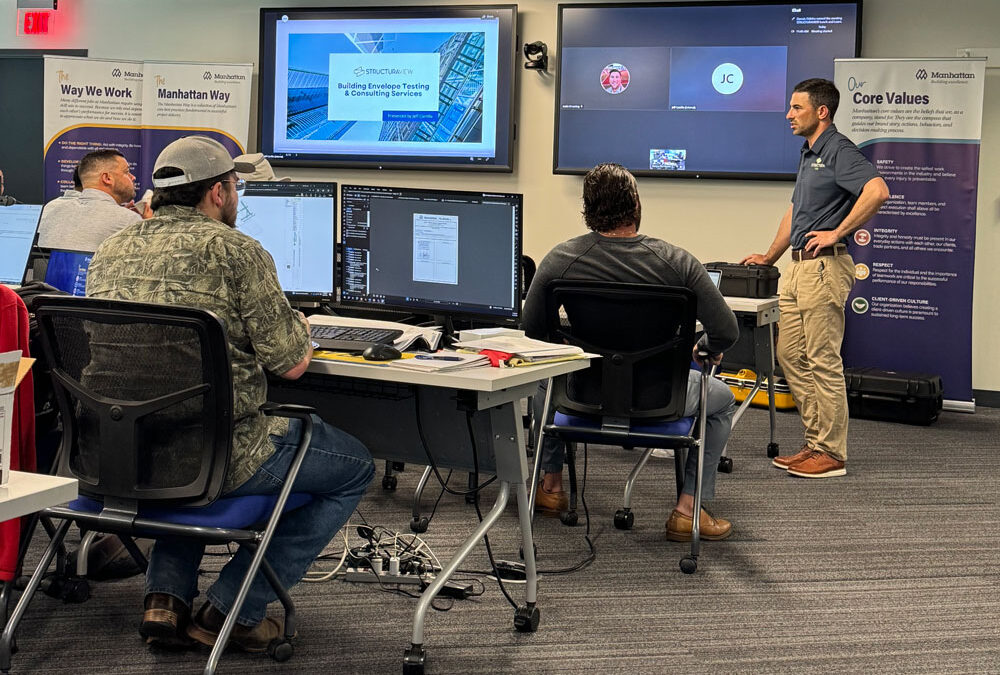

By comparison, the use of thermal imaging on a drone can be equally as effective for identifying delaminations. The voids in the road will reflect different temperature readings than the rest of the deck that can be documented and imaged under the proper conditions. One of the biggest advantages is that we do not need to operate on or even directly over the roadway to properly document, which means no road closures are required. The team required to successfully deploy this process includes a simple 2 man team. In most cases, the cost to perform a thermal bridge scan without needing road closures can save thousands of dollars a day.

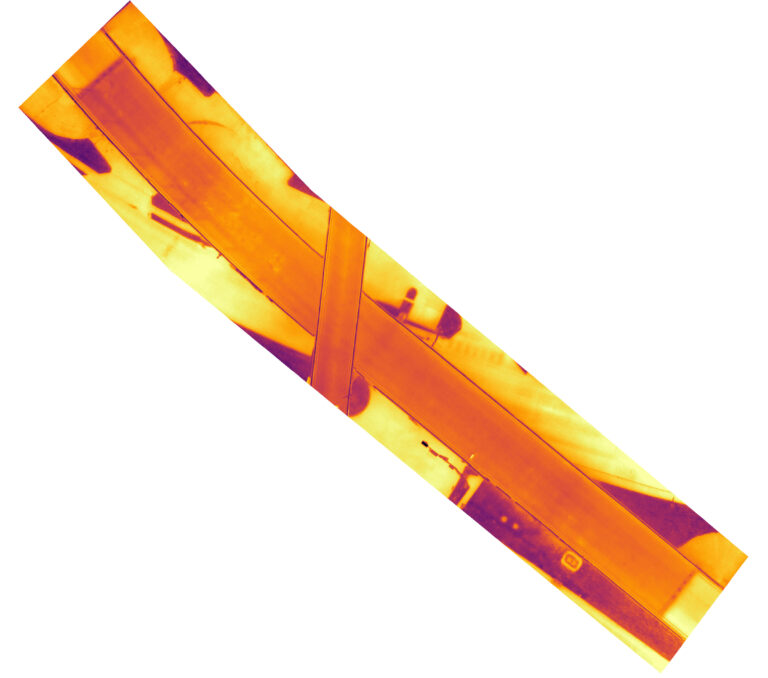

For this project, we were deployed to document and survey 10 different bridges associated with the Dallas North Tollway roadway. For each bridge, we completed redundant documentation capturing RGB and Thermal Spectrum imagery and video. Our end result was to deliver video and stitched images of the roadways that allowed the engineer to have the ability to view every inch of the bridge deck without any obstacles or cars in the way.

From an FAA perspective, if you are up to date on legal operations, you know it is illegal to operate directly over people or people in moving objects, such as cars. The operation was pre-planned to not have to fly directly over active traffic lanes anticipating having to operate during active traffic times. Our goal was to pick a time the least amount of traffic would be out while still working within our ideal thermal operating window. Fortunately, that day we had a lot of solar loads allowing us to work from roughly 9 pm to 1 am to complete all 10 bridges in one night. Our original plan was to split it up over 2 nights, but due to weather constraints, we had to finish everything in one.

We needed to capture enough video and images without cars to be able to stitch together an overhead image of each bridge then kept cars out of it completely. This required flying our preplanned flight paths sometimes multiple times to ensure this was done properly. Fortunately, traffic was lighter than expected making this task much easier to accomplish. We were able to successfully capture images documenting the entire bridge without cars in the way with both thermal and RGB imagery and video. We were then able to take those images and stitch them together to create overhead images of each bridge for detailed review and analysis, mapping out delaminations for further inspection and validation.

The Successes

In partnering with an engineer on the project, we were able to complete this project as expected. We were able to capture all our images while abiding by FAA rules and regulations to successfully capture every inch of the bridge without cars or other obstacles being in the way. We were able to save the end client thousands of dollars by not having to pay for road or lane closures and successfully documented each bridge within our operating window to be able to identify thermal anomalies we suspected to be delaminations in each bridge. Mapping out the exact location of each delimitation was vital to the success of the project. Through the experience of our team, we were able to overcome difficulties and challenges to efficiently complete the whole project in one night when the original plan involved 2 nights for completion.