For this case study, we worked alongside a commercial roofing contractor that specializes in repairing and replacing large commercial roofs. The roof needed a maintenance inspection and was nearly 65,000 square manufacturing facility in Chester, SC. The construction of the roof was a typical Modified Bitumen. The first layer of the roof was a metal deck, followed by ISO board insulation and a membrane that was constructed of the usual welded base and cap sheets. On each maintenance inspection we conduct, our top priority is to provide an unbiased report.

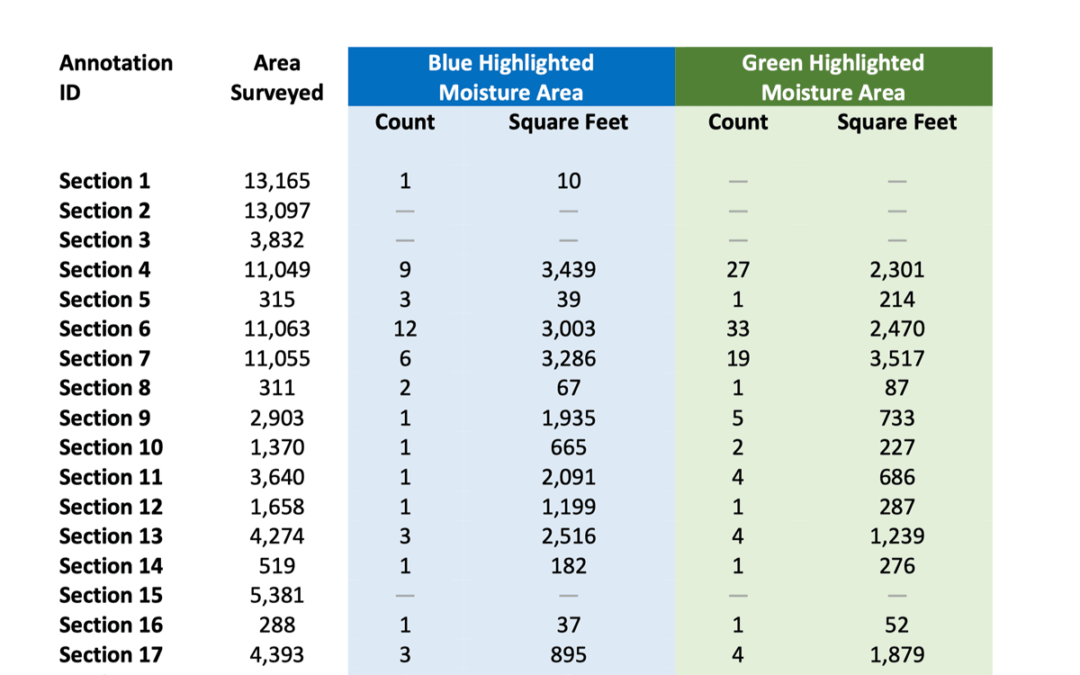

We use a repeatable process of mapping moisture on each roof. While we surveyed other similar roofs that experienced damage caused by the same weather conditions, the findings of the moisture inspections for this facility were completely different.

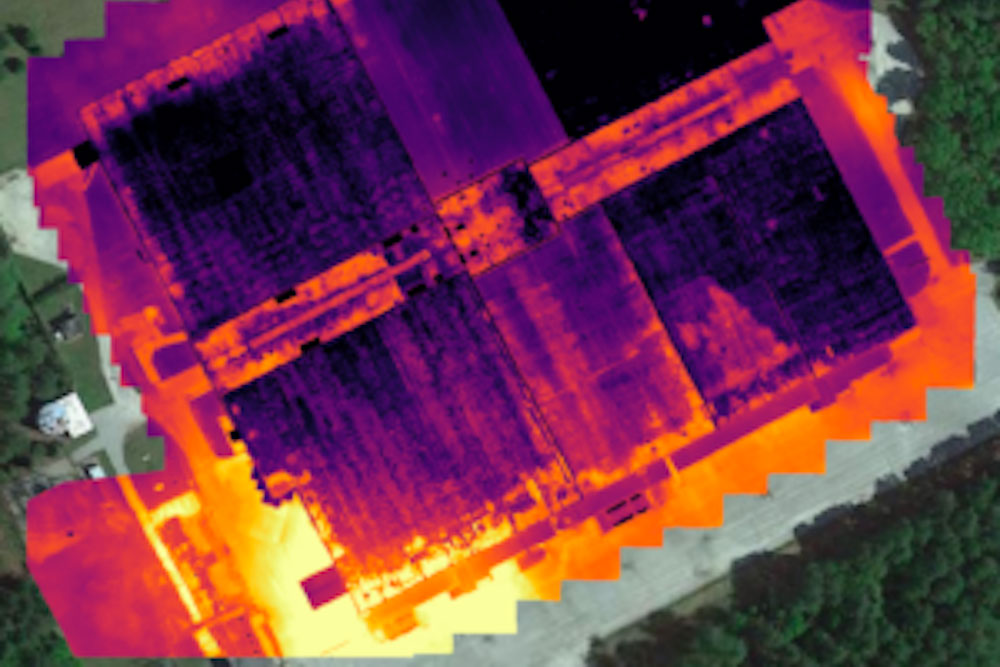

On this maintenance inspection, we were asked to identify suspected moisture present on the roof. When we capture infrared photos of the roofs we inspect, we can’t simply view the thermal images to identify suspected areas of moisture. We take into consideration the effective working range of the equipment we use. We also consider weather conditions and the time of day that the inspection was conducted. Finally, we examine and compare the exterior conditions present on the roof with the thermal images we collected. We look for things like debris, ponding water, discoloration, and mechanical equipment that could be giving off thermal readings. We do this to ensure that those thermal signatures are not accidentally being interpreted as areas of suspected moisture.

The roofing contractor that we were working with on this maintenance inspection took core samples on both wet and dry areas of the roof. When we compared our suspected moisture findings with the core sample results, there was a correlation, which meant that our thermal observations were validated.

Read more about Routine Maintenance Inspection Programs