This facility is a small smoked meats processing company that supplies grocery stores and restaurants throughout the country and is based right here in the Tampa Bay area. Like all food processing facilities, they follow strict guidelines to maintain a safe and healthy work environment. Part of these guidelines includes properly maintaining the building to ensure contaminants stay outside the building and do not jeopardize the plant’s ability to deliver the highest quality products with the least amount of downtime.

Your building’s roof and wall structures are literally the physical barriers that protect the day-in and day-out processes of the business from the elements of mother nature. Regularly inspecting and performing preventative maintenance enables companies to identify problems early before they become major issues that cause the business to temporarily shut down. Any amount of time your business has to be shut down equates to a loss of income and comes with substantial expenses.

We recently launched a preventative maintenance program that commercial property owners are finding value in. Through this program, our goal is to provide you with a good visual understanding of the extent of damage your roof currently has, connect you with quality contractors to help remedy the issues, and then perform a post-repair inspection to confirm all the issues were addressed and repaired properly. This gives you proof that you are making efforts to properly maintain your roof and gives you historical data to prove roof conditions when you need to file insurance claims. For this project, we were able to be involved in the entire process.

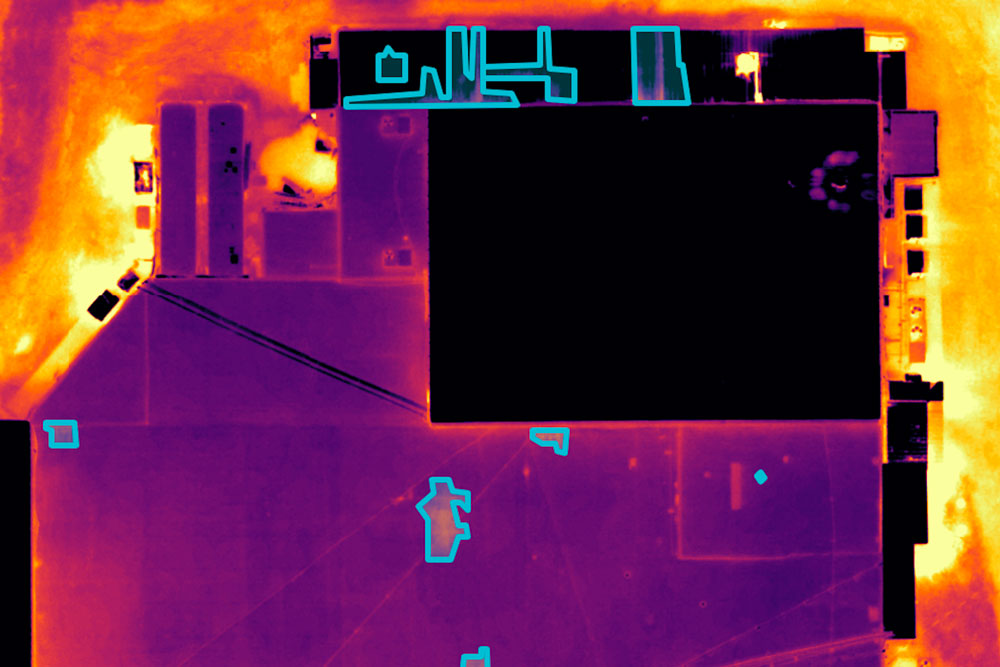

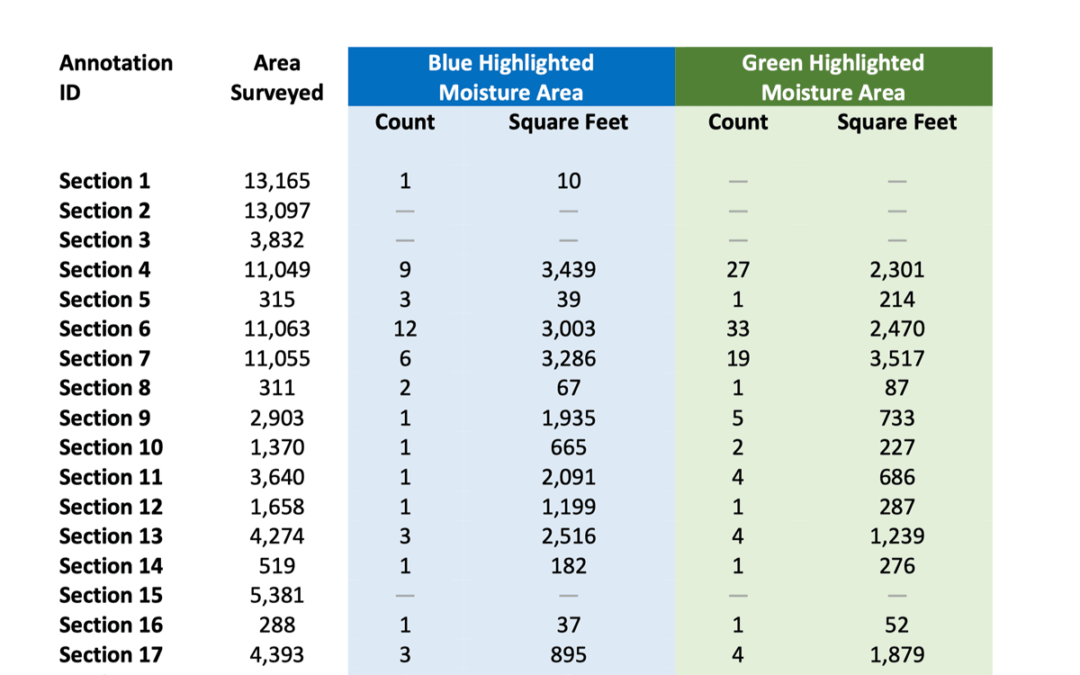

TPO and Metal roofs have proven to be quality roof systems over the years, but as they age, problems are bound to arise. This roof is estimated to be about 36,000 square feet in total size. After performing a thermal roof scan to study the condition of the roof, 8 different locations were observed that we suspected to be wet totaling 927 square feet. After identifying these areas we suspected to be wet, we contacted one of our preferred commercial roofing contractors to go physically inspect the areas we suspected problems and estimate the cost for repairs.

Fortunately, the wet areas observed were caught early enough making the cost for repairs manageable. As you might guess, any time you have water or moisture trapped in a structure, the problem will typically only get worse. Mold is one of those hidden side effects of trapped moisture that can cause major issues if not properly addressed in a timely manner.