Client Challenge

The client faced water leaks within their 18-story building, likely stemming from facade deterioration. Their goal was to pinpoint potential sources of moisture intrusion. Additionally, the city’s green initiative, focused on energy efficiency, added pressure to address the building’s issues while complying with any applicable regulations.

Recognizing the need for a thorough facade survey to assess the damage and plan remediation within budget constraints, the client turned to Structura View for assistance. Our task included identifying internal moisture, pinpointing physical facade defects, and mapping visual and thermal observations to identify areas of concern.

Wall Data

Location: Denver, Colorado

Facade Composition: EIFS

Surface Paint: Yes

Leaks Reported: Yes

Solution Strategy

To start the investigation, we performed a drone based visible and thermal scan. The initial analysis of the data revealed a large number of anomalies observed in each of the the building façades: North, East, South, and West. This necessitated that each facade of the building to be delivered in its own report. In order to provide meaningful data, each façade is divided into multiple sections with anomalies being aggregated into color coded groups.

Below is an example of the summary of defects that were documented and that were included in the client’s report. The summary includes details and a description of observations for each defect category along with the defects’ color code. The summary of defects are aggregated for North, East, South, and West facades.

|

Cracks w/ or w/out Crazing: 1,267 areas with individual or larger diameter cracks were visually observed on the east façade. Some of the cracks or more defined or larger as compared to most cracks observed with other small cracks and crazing around them. Others are individual cracks that vary in gap and length but are isolated individual cracks. |

|

|

Crazing/Web Cracks: 932 areas with hairline cracks were observed on the east façade. Many of the cracks observed in this category were more like crazing or spider cracks as there were often a lot of hairline cracks in one area. |

|

|

Exposed Openings: 80 locations were observed and notated as observed openings in the façade. These locations vary from tops of beams on the first floor not having any grout or sealant waterproofing the top of the beam to the building to observed openings in the façade revealing reinforcement mesh. |

|

|

Sealant Cracks or Failures: 28 locations were observed to have sealant failures or cracks in. These locations were primarily around the decorative sections of the walls. |

|

|

Missing or Cracked Grout: 40 areas were observed to have missing or cracked grout in quadrants 9 and 10 between the 1st and second floor of the entire east façade. Some of these observations may have been repaired with a sealant in the past and still have cracks in them. |

|

|

Organic Growth: 4 locations of organic growth was observed on all facades of the building. There is some white discoloration present on the exterior of the walls near some cracks and miscellaneous area, but the majority of this can be observed between the 1st and second floors in quadrants 9 and 10 of this report. |

|

|

Chips, Peeling Coating: 86 locations were observed to have chipped paint or chipped pieces of the façade. |

|

|

Rust/ Oxidation: 112 locations were observed with either rust stains on the walls or decorative metal on some of the balconies that were rusting. |

|

|

Unknown Object or Shadow: 216 locations were observed and in many areas it was difficult to tell what was going on. I suspect many of these locations will correlate with openings in the wall exposing reinforcement mesh. Further investigation is recommended to study these locations in more detail. |

|

|

Thermal Anomalies: In the thermal imagery we see mechanical attachments and fasteners in the wall throughout the entire façades, indicating we captured the building in an optimal time frame to observe suspected moisture. 49 thermal anomalies were observed and highlighted in this report for further review and testing. Each of these thermal anomalies were generally small. Thermal data sets are included in this report with each quadrant’s image sets. |

|

|

Ponding Water: 7 locations were observed on flat surfaces in the East facade, quadrants 9 and 10 that had standing water at the time of the scan. This water was holding near a transition in the metal work on the façade and is suspected to be allowing moisture to get into the façade that may not be visible in the thermal imagery. |

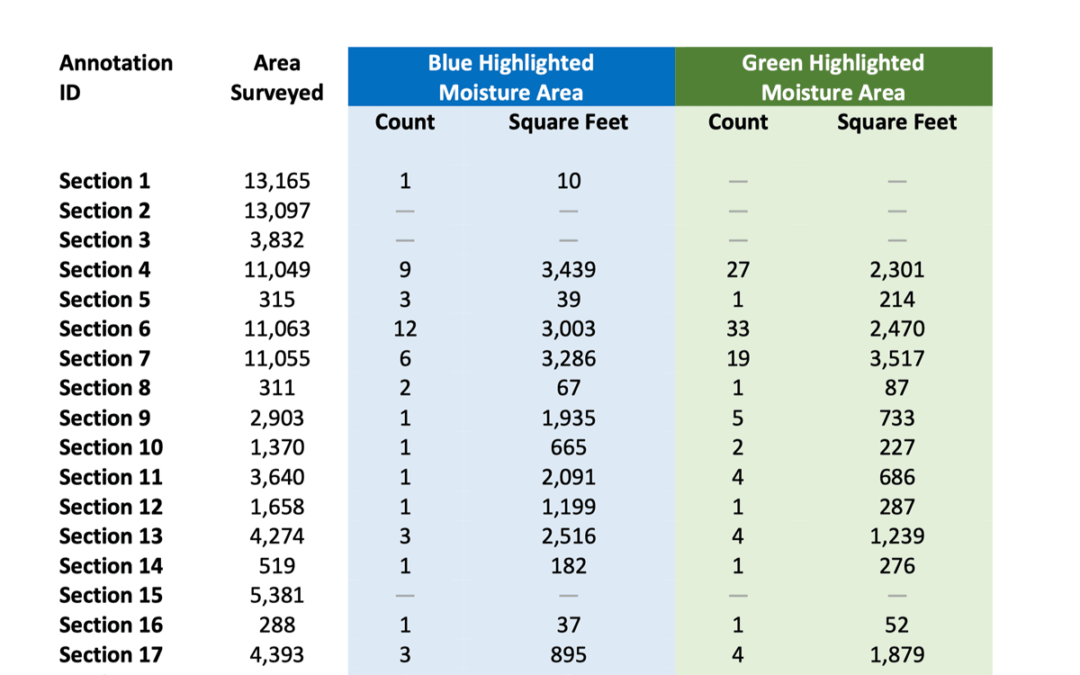

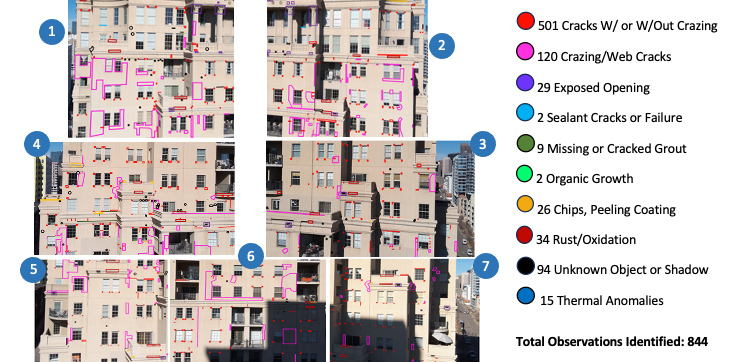

South Facade Overview Showing Section Defects

Below is a sample of an overview image included in the report documenting issues with the Southern façade. Because each anomaly type is aggregated into color coded defect groups, it’s easy to tell which type of repairs are necessary as well as being able to prioritize and formulate a long-term budget.

Section Close-Up

Once the entire façade overview has been documented, we show a close-up of each section in the report. After each section close-up, we document a sample of each defect type. Below is a close-up of East facade section 4.

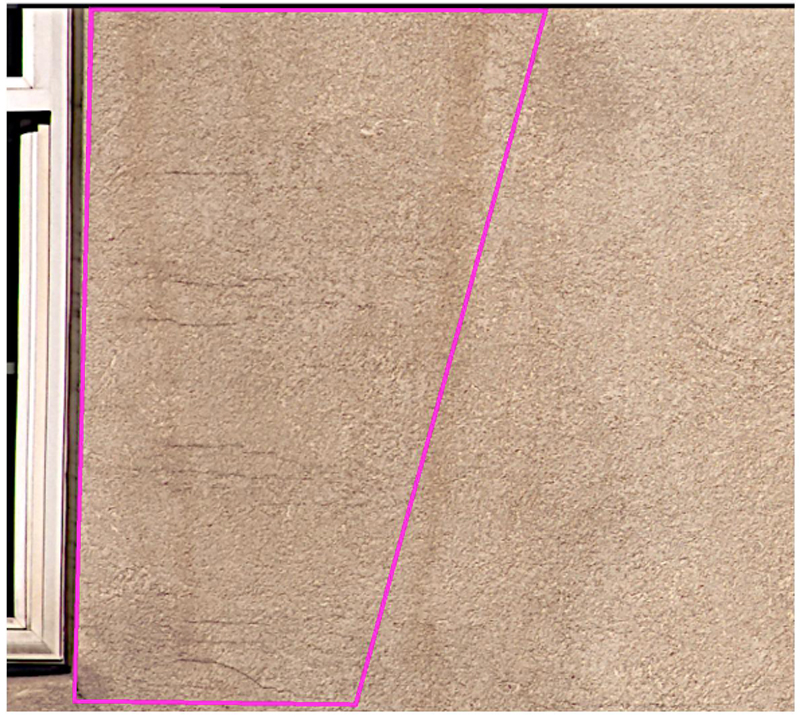

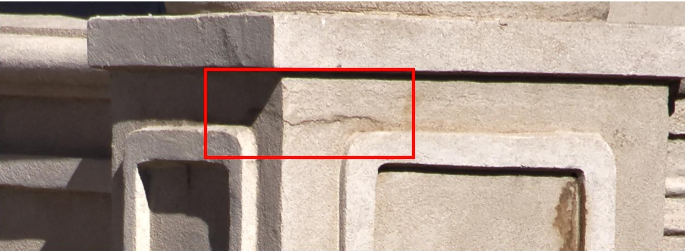

Close-Up of Defect Types

Below are close-ups of the most common defects.

Example Image: Exposed Opening

Example Image: Sealant Failure

Example Image: Unknown Object

Example Image: Crazing, Web Cracks

Example Image: Crack

Example Image: Rust/Oxidation

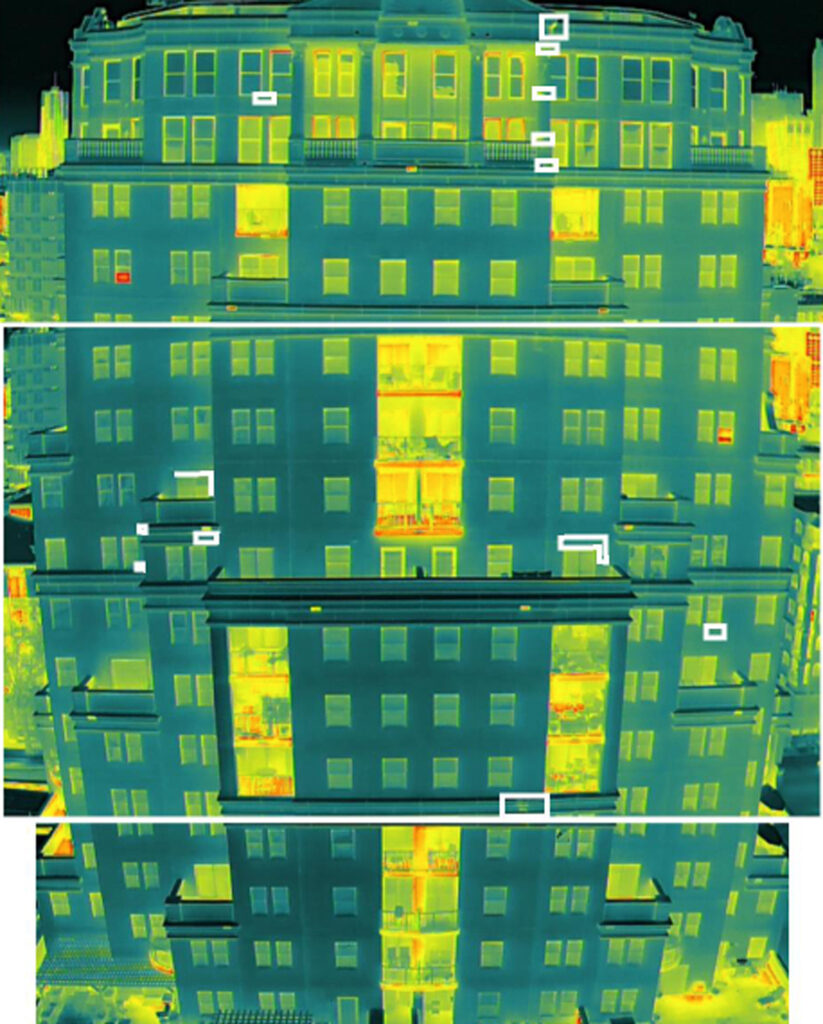

Thermal Facade Survey

In conjunction with the visual survey, a thermal scan was performed on the facade. Critical to the success of the thermal scan, is that the thermal scan is taken when the temperature differences in the walls are maximized. We plan the timing of each thermal scan for the North, South, East, and West to maximize the optimal temperature differences. The resulting thermal imagery reveals nicely defined hot and cold spots. Some hot spots correlate to material differences in the facade and other hot spots correlate to suspected moisture. We analyze the imagery to determine which hot spots likely correlate to suspected moisture intrusion and which hot spots correspond to material difference and should be ignored.

The below thermal image for the South facade shows hot spots on balconies, doors, scupper openings, chips, and windows which are due to material differences. There are some hot spots in columns and walls which are areas of suspected moisture and will need physical testing for verification. The suspected moisture areas are outlined in white.

Included in the facade report are close-ups of all identified thermal anomalies. Below is a close-up of one of the columns we identified in the overview image as having suspected moisture intrusions. Notice that only some of the thermal anomalies are outlined. The reason is that some of the thermal anomalies correspond to holes and chips in the column and are not from moisture intrusion, although they may be the source of the moisture intrusion.

To Sum Up the Results

The visual report shows the areas of concern on the facade, highlighting physical defects that could lead to moisture intrusion or ongoing damage. In many instances, both significant and minor thermal anomalies detected in the imaging of the building’s EIFS construction corresponded with visual irregularities. With the details from the reports, the client can initiate their physical investigation to validate the data and establish short- and long-term remediation budgets.